July 3/2009

Japan Fair Trade Commission

From December 2008 to March 2009, the Japan Fair Trade Commission (JFTC) conducted a survey regarding the utilization of biomass-derived fuels (biofuel) for blending with gasoline by interviewing related businesses and government offices. Subsequently, JFTC analyzed the result of the survey under the Antimonopoly Act from the viewpoint of establishing an environment where the Direct Blending Method and the ETBE Method should be evaluated and selected through competition in the market, and reviewed the measures required to ensure an equal footing between these two blending methods. The JFTC publishes these views.

1. Survey

(1) Facts

A. The Revised Kyoto Protocol Target Achievement Plan (Cabinet Decision of March 28,2008) (see Annex 1) states that “The spread of biofuels, including fuels for transportation, shall be promoted.” However, there are two methods of using biomass-derived fuels for blending with gasoline: a method whereby bioethanol is directly blended with gasoline (hereinafter referred to as the “Direct Blending Method”) and a method whereby ETBE is produced from bioethanol and is then blended with gasoline (hereinafter referred to as the “ETBE Method”) (see Annex 2). At present, E3 is produced and sold as a product made by the Direct Blending Method.

B. With regard to the Direct Blending Method,demonstration projects have been carried out by Osaka Prefecture under commission from the Ministry of the Environment, etc., and in Miyakojima under commission from the Ministry of the Environment, the Ministry of Economy, Trade and Industry, etc. As for the ETBE Method, a demonstration project was carried out mainly by the Petroleum Association of Japan with subsidies from the Ministry of Economy, Trade and Industry (until the end of FY2008).

C. JFTC carried out surveys on businesses using these methods, taking the position that these two blending methods should be evaluated and selected through market competition. As a result, JFTC found the following facts:

(a) The Petroleum Association of Japan has repeatedly stated that the Direct Blending Method has problems.

(b) Petroleum wholesalers are negative about supplying gasoline as raw material for the Direct Blending Method.

(c)Service stations (hereinafter referred to as “SS”) affiliated with petroleum wholesalers have not sold products made by the Direct Blending Method.

It can be judged from (b) and (c) that consumers cannot make a free choice due to the limited volume of products by the Direct Blending Method.

(2) Background

A. Since the vapor pressure rises when ethanol is directly blended with gasoline, because of the existing JIS standards for vapor pressure, regular gasoline with standard specifications cannot be used for the Direct Blending Method (see Annex 3).

B. The Petroleum Association of Japan and petroleum wholesalers think it difficult to achieve the high objectives set by the Ministry of the Environment, such as the introduction of E10.

2. Measures in the future

The following measures are necessary for establishing an environment in which the Direct Blending Method and the ETBE Method are evaluated and selected through market competition:

(1) JFTC’s measure – clarification of its view under the Antimonopoly Act Based on the actual situation described in 1(1), JFTC will clarify its views concerning petroleum wholesalers in accordance with the Antimonopoly Act as follows:

A. If the Petroleum Association of Japan forces each petroleum wholesaler not to cooperate in manufacturing and selling products made by the Direct Blending Method or if petroleum wholesalers jointly decide not to cooperate in manufacturing or selling products made using the Direct Blending Method, it would constitute a violation of the Antimonopoly Act. Moreover, if the Petroleum Association of Japan continues to state a negative opinion against only one of the two blending methods, the member petroleum wholesalers may develop a common understanding that the negatively stated blending method should not be adopted. The Petroleum Association of Japan should fully understand and acknowledge this.

B. If petroleum wholesalers uniformly prohibit their exclusive distributors from dealing with products by the Direct Blending Method at SS that are affiliated with the distributors, it is highly likely that businesses manufacturing and selling products by the Direct Blending Method will have difficulty in securing distribution channels due to the following:

(a) even if the prohibition is a result of each petroleum wholesaler’s decision, almost all petroleum wholesalers are highly likely to prohibit the distributors from the dealing under the situation described in 1 above, and

(b) in Japan’s gasoline market, the proportion of gasoline distributors exclusively affiliated with a petroleum wholesaler is high, and it is actually difficult to create a new sales network of SS.

Since this action by petroleum wholesalers unfairly forces another party not to trade with competitors and may reduce the trade opportunities of such competitors, this action may fall under Article 11 of the Designation of Unfair Trade Practices

(Trading on Exclusive Terms) and be in violation of the Antimonopoly Act.

If a petroleum wholesaler prohibits its exclusive distributors from selling the products of other companies without assigning the petroleum wholesaler’s trademark, this does not fall under Article 21 of the Antimonopoly Act (exemption with regard to the exercise of intellectual property rights). At the least, if,because exclusive distributors cooperate in carrying out demonstration projects for the Direct Blending Method in various areas, each affiliated SS separates the gasoline pump and underground tank used exclusively for the product by the Direct Blending Method from others and sells the product by expressly indicating that the product supplied from the pump is not a product of the petroleum wholesaler whose name is clearly displayed on the gas station signs, any act prohibiting the sale on the grounds of trademark rights may be deemed violating the Antimonopoly Act.

(2) Essential measures by related government authorities

The facts described in section 1 above are related to the regulations and views of administrative agencies. There is a concern that these facts may cause actions by petroleum wholesalers to come under section 2.(1)above. Related agencies should

take the following measures to establish an environment whereby the Antimonopoly Act is not violated and to promote both blending methods:

A. To dispel any related doubts by businesses, the Ministry of the Environment and the Ministry of Economy, Trade and Industry should cooperate with each other to support the provision of any required information concerning the promotion of the use of biomass-derived fuels for gasoline in the future.

B. With regard to the use of regular gasoline with standard specifications for the Direct Blending Method, the Ministry of the Environment should consider whether to review the vapor pressure standards, fully weighing the environmental effects.

C. With regard to the methods of blending bioethanol, the Ministry of Economy, Trade and Industry should inform the Petroleum Association of Japan and each petroleum wholesaler that because the systems for both the ETBE Method and the Direct Blending Method have been established, businesses can make a free choice.

Annex 1

Revised Kyoto Protocol Target Achievement Plan

The Revised Kyoto Protocol Target Achievement Plan (Cabinet Decision of March 28, 2008) states as follows: “With regard to using biofuels for transportation (gasoline and light oil), we will cope with such problems as competition with use for food, the stability of supplies, and economic efficiency. In addition, the spread of biofuels, including transportation fuels, will be promoted mainly through biofuels-related tax systems and other economic incentives, establishing technology using cellulose from rice straw and other materials that do not compete with food, large-scale demonstration projects for expansion of the production of domestic biofuels, and developing automobiles that use biofuels in high concentrations.

Moreover, a system for securing the quality of biofuels will be established and we will support joint efforts between those engaged in agriculture, forestry, and fisheries, who are the producers of the raw materials for biofuels, and the manufacturers of biofuels.”

Moreover, the “Appendix 1: List of Measures Concerning Energy-Derived Carbon Dioxide” attached to the Plan states that the “use of biomass heat: 3,080,000 kl (including biofuels used for transportation (500,000 kl)). “Reference 2: Grounds for the Estimated Amount of Emissions Reduction due to the Concrete Measures Listed in Appendices 1 to 6” states as follows: “With regard to transportation biofuels, there are problems in lowering the cost of cultivating resource crops without causing any adverse effects on food production, and in improving the efficiency of the collection and transportation of the resource crops. It is essential to solve these problems. Hence, demonstrations of gasoline blended with 3% bioethanol (E3) and ETBE have been carried out in Japan since FY2007 (including demonstrations that are in the planning stage in some areas), such as a demonstration of the distribution of ETBE through 50 service stations in the Tokyo metropolitan area, large-scale demonstrations of E3 in large city areas and starting large-scale demonstrations of bioethanol in two areas in Hokkaido and in Niigata. In addition, we will support the development and introduction of technologies for producing and using biofuels, such as the establishment of the technology for using the cellulose contained in rice straw and other materials that do not compete with food and the development of the technology for using gasoline blended with 10% bioethanol (E10). The use of biodiesel fuel (BDF) has also been promoted in some areas. Moreover, a plan targets introducing 240,000, which is being put into shape, to 500,000 kl of transportation biofuels by 2010 through supporting joint efforts between agricultural, forestry, and fishery workers, who produce the raw materials for biofuels, and the manufacturers of biofuels, and establishing biofuels-related tax systems.”

Annex 2

Bioethanol-Blended Gasoline

Bioethanol-Blended Gasoline

1. Bioethanol-blended gasoline

Since the combustion of bioethanol1 does not increase the amount of carbon circulating on the surface of the earth, biogasoline is carbon neutral. Biogasoline is an effective means of reducing greenhouse gas emissions,since the amount of CO2 produced by the use (combustion) of biogasoline is not included in the amount of greenhouse gas emissions.2

(1) E3

E3 is gasoline blended directly with 3% bioethanol. It is advantageous in that its production is simple. On the other hand, it has the following disadvantages: (a) because ethanol is highly hydrophilic, unlike gasoline, strict moisture control must be carried out; and (b) when ethanol is blended with gasoline, the vapor pressure may exceed the upper limit prescribed for the prevention of air pollution.

Thus, the distribution of E3 requires some changes to the existing distribution network and the procurement of gasoline with a lower vapor pressure.

(2) ETBE gasoline

ETBE gasoline is gasoline blended with ETBE, a chemical compound of bioethanol and isobutene. ETBE has long been examined as a base material for gasoline and has the following advantages: (1) because it can be treated in the same way as gasoline, the existing distribution network can be used without any modifications; and (2) it can be blended with the existing gasoline without raising the vapor pressure. However, compared with fuels by the Direct Blending Method, such as E3, it is

necessary to add the process of compounding ETBE.

Therefore, to popularize ETBE gasoline, it is necessary to establish facilities for compounding ETBE and to secure isobutene.

(3) Cost of producing and distributing E3 and ETBE gasoline

The distribution of E3 requires the mixture of ethanol with the gasoline to be carried out just before loading it onto tank trucks in order to prevent the ethanol from coming into contact with moisture. Since many oil tank facilities in Japan do not

have blenders and other necessary equipments, it seems necessary to newly install such equipment. In addition, each oil refinery will incur the cost of producing gasoline with a lower vapor pressure.

Compounding ETBE requires establishing ETBE compounding facilities and securing isobutene supplies. Since the existing facilities producing MTBE3 can be used as ETBE compounding facilities, and because each oil refinery produces isobutene as a byproduct during the process of refining oil, it seems possible to make the initial investment lower than in the case of E3. However, if ETBE increases and the required amount of isobutene exceeds the amount produced during the process of

---------------------------

1 Ethanol (C2H5OH) produced through the fermentation and distillation of biomass sources, such as sugarcane and corn.

2 According to the United Nations Framework Convention on Climate Change,the ultimate goal of this Convention is to “stabilize greenhouse gas concentrations in the atmosphere at a level that will prevent dangerous human interference with the climate system.”

3 MTBE is the acronym of methyl tertiary butyl ether. It is a kind of ether like ETBE and has similar characteristics to ETBE. It has been regarded as effective for the improvement of the octane number and the reduction of carbon monoxide. Because the production process is similar to that of ETBE,MTBE production facilities tend to be converted into ETBE production facilities.

refining oil, it will be necessary to produce or procure additional isobutene supplies. Moreover, if the amount of ETBE exceeds the capacity of the existing MTBE production facilities used as ETBE compounding facilities, investments in new facilities will become necessary. In this case, the cost will increase as the amount of ETBE gasoline increases.

Therefore, while a higher level of initial investment is necessary for E3, the average cost of ETBE will increase as the amount increases. Because the average cost gradually decreases in the case of the Direct Blending Method for E3, the cost of ETBE could exceed the one of E3 if the amount of ethanol used reaches a certain level.

2. Situation in other countries

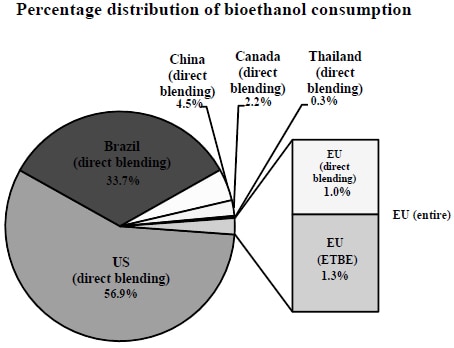

The table below shows the percentage distribution of bioethanol consumption among the main countries and areas that consume ethanol for fuel. Of the methods of using bioethanol, the Direct Blending Method is used in the US, Brazil, China, Canada, and Thailand. Although the ETBE Method is used for only about 1% of bioethanol consumption in the world, it is used

for more than a half in the EU.

The Direct Blending Method is popular in the US and Brazil because research on blending domestic ethanol with gasoline began there in the 1970s. The use of ethanol as a fuel began when the oil price rose sharply due to the oil crisis. At that time,the technology for compounding ETBE and other types of ether had not yet been established. Since the installation of equipment for the Direct Blending Method, such as the blending equipment in oil tank facilities, was promoted, the Direct Blending Method has become popular.

In the EU, the ETBE Method was introduced earlier. The Direct Blending Method requires investments in blenders and other equipment at oil tank facilities to prevent moisture from being mixed with the fuel. While the US has installed such equipment since the 1970s as described above, the EU could not take a lot of time for making investments in such equipment since the EU needed to introduce bioethanol in a comparatively short time. In the US, when the use of bioethanol began, the technology for compounding ether had not yet been established. On the other hand, since the EU had experience in using MTBE, a kind of ether, it seems to have been easier to convert MTBE compounding facilities into ETBE compounding facilities.

Incidentally,there is no country in the world where any law or government policy obliges the adoption of either the ETBE Method or the Direct Blending Method.

Annex 3

Vapor Pressure

1. Current situation of the vapor pressure regulations

To prevent air pollution and ensure cold startability, the JIS K 2202 gasoline standard provides that the vapor pressure shall be “44 to 78 kPa (the upper limit of vapor pressure for the cold season shall be 93 kPa and the upper limit of that for thes ummer season shall be 65kPa)”. Although this is not a compulsory standard, it is also used as a standard under the Act on the Quality Control of Gasoline and Other Fuels. If the gasoline meets this standard, measuring instruments, etc. are allowed to display an SQ mark according to the SQ mark system.

This standard for vapor pressure was introduced in 2004 based on the Central Environmental Council’s report that a standard should be established for the prevention of air pollution.

If gasoline is blended with 3% ethanol, the vapor pressure rises by 6 to 7 kPa due to the azeotropic phenomenon. Therefore, the vapor pressure of gasoline blended with ethanol should be limited to the standard level.

Since the higher the vapor pressure of the gasoline is, the more gasoline can be extracted from crude oil,petroleum wholesalers can more effectively produce gasoline by raising the vapor pressure close to the upper limit. In the summer season in particular, the vapor pressure of gasoline from wholesalers becomes close to the upper level (such as 64 kPa). Therefore, if ethanol is generally blended with the gasoline for distribution in Japan, the vapor pressure often exceeds the upper limit and does not meet the standard.

Due to this vapor pressure standard, it is necessary to produce special gasoline for the production of E3, which may form a hindrance to the spread of E3. “Spread of Eco-fuel for Transportation (Supplementary Version),” which was compiled in January this year by the Conference for Eco-fuel Utilization Promotion, states that “Of the quality standards for E10 fuels, with regard to the regulation of vapor pressure, which is greatly influenced by the blending of ethanol, because some foreign countries have carried out,or are planning to carry out, measures for using the regulated values for E10 fuels flexibly on condition that the air quality standards for fuel evaporative emissions should be maintained, it seems necessary to consider how to reasonably execute the regulation of vapor pressure according to the situation in Japan, while continuing to assess overseas trends.”

2. Gasoline with a reduced vapor pressure

To produce gasoline with a lower vapor pressure, it is necessary to reduce the light components (such as butane) in gasoline. This will result in a reduction in the amount of gasoline extracted from crude oil. Since butane is less expensive than gasoline, the exclusion of butane from gasoline will increase the cost.

It is generally said that 45% of the gasoline distributed in Japan is FCC gasoline. FCC gasoline is made using a fluid catalytic cracker (FCC), which converts heavy gas oil extracted from crude oil into gasoline. FCC gasoline contains a lot of butane. Therefore, oil refineries that use a lot of FCC gasoline will have considerable trouble in producing gasoline with a

lower vapor pressure.

The quantity of FCC gasoline and the quantity of butane contained in FCC gasoline vary greatly depending on the quality of the imported crude oil.4 Thus, it can be considered that whether it is easy to produce gasoline with a reduced vapor pressure varies according to the facilities or the quality of the imported crude oil.

Although whether each petroleum wholesaler’s existing facilities can produce gasoline with a reduced vapor pressure depends on the wholesaler’s facilities and capacity, some wholesalers seem to need to make investments in equipment. Even if they can produce gasoline with a reduced vapor pressure, this will incur a certain cost,because the higher the vapor pressure of

the gasoline is, the more gasoline can be extracted from crude oil, and because the closer the vapor pressure of the gasoline is to the upper limit, the more effectively wholesalers can produce gasoline. In addition, since each wholesaler maximizes profits through the use of its facilities, such as tanks, plants, and lines, changing its facilities will incur a certain cost if it

newly produces gasoline with a lower vapor pressure.

In the interview survey, wholesalers stated the following reasons for their reluctance to supply gasoline as a raw material for the Direct Blending Method: (a) they have no available capacity to supply it; (b) they have no facilities to produce gasoline with a reduced vapor pressure, or the cost of producing it is excessive; and (c) they cannot ignore the moral responsibilities

involved in supplying a raw material for the production of gasoline with a nonstandard vapor pressure.

---------------------------

4 The proportion of light components in crude oil varies according to the petroliferous area.

Reference

○Guidelines Concerning Distribution Systems and Business Practices under the Antimonopoly Act (excerpt)

2. Restrictions on Distributors’ Handling of Competing Products

(1) (Omitted)

(2) In cases where a restriction on the handling of competing products is imposed by an influential manufacturer in a market (Note 4), and if the restriction may result in making it difficult for new entrants or competitors to easily secure alternative distribution channels (Note 5), such restriction is illegal as unfair trade practices (Article 11 (Dealing on Exclusive Terms) or 13 (Dealing on Restrictive Terms) of the General Designation).

(Note 4) (Omitted)

(Note 5) Whether or not a restriction “may result in making it difficult for new entrants or competitors to easily secure alternative distribution channels” is to be determined, taking comprehensively into account the following factors:

a. Structure of the market (market concentration,characteristics of the product, degree of product differentiation,distribution channels, difficulty of entry into the market, etc.);

b. Position in the market of the manufacturer that imposes the restriction (in terms of market share, rank, brand name, etc.);

c. Number of distributors affected by the restriction, and their position in the market; and

d. Impact of the restriction on the business activities of the distributors (extent, manner, etc. of the restriction).

As an element of the market structure listed in a. above, other manufacturers’s behaviors are also to be considered. For example, in cases where two or more manufacturers respectively and in parallel restrict the handling of competing products, it is more likely to result in making it difficult for new entrants or competitors to easily secure alternative distribution channels, compared to cases where only one manufacture does.

(The rest is omitted.)

*Every announcement is tentative translation. Please refer to the original text written in Japanese.